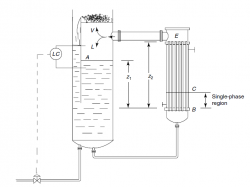

The vertical Thermosiphon Reboiler is design to vaporized CUMENE & CHP(-0.85kg/cm2g, 71C from reboiler datasheet) of liquid mixture. Be heated by steam (1.8kg/cm2g, 130C) at a distillation column bottom. And, the allowable pressure drop on the cold side is 0.14 kg/cm2g (but it already includes static head), is this “-0.85kg/cm2g” the inlet pressure of reboiler instead of pressure at the distillation column bottom?

The process fluid,CUMENE in the tube side be heated from 71C to 114C.

CUMENE is unsaturated at inlet of reboiler cause of static head, and, process fluid will be sutured as temperature increase along the reboiler. The vapor will also form as the pressure decrease along the tube length.

There is input function about required liquid static head in HTRI, and it also tell relative location between the tower and reboiler. And, this static head will affect the vaporization ratio (vapor rate/total feed rate).

In the given duty condition, increasing static head will increase the circulation ratio and decrease the vaporization ratio. In the vacuum distillation column case, what is the reason that static head is always less then reboiler length?

Is vaporization ratio greater than 0.4 and vacuum distillation column case, the Forced-Circulation Falling Film type Reboiler will be better choise ?

Please correct me if I make wrong statement above.

I really appreciated your help.

Thank you very much.

FB

FB