Today's blog entry provides some guidelines for sizing of vertical oil treaters. The procedures described in this blog entry do not give the overall dimensions of the treater, which may include inlet gas separation and free-water knockout sections, dependent on the upstream separation vessels. However, they do provide a method for specifying heat input required and a minimum size for the coalescing section (where the treating actually takes place), and provide the design engineer with tools to evaluate specific vendor proposals.

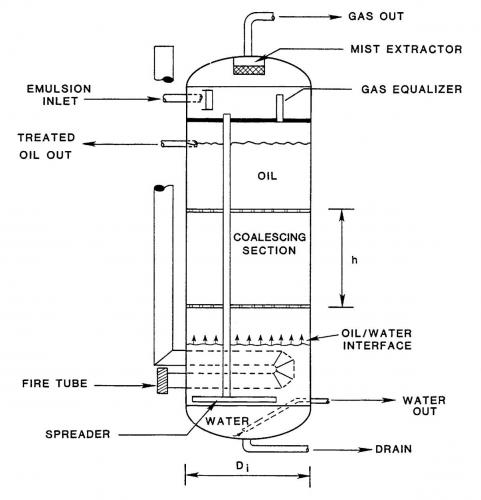

Today's blog entry provides some guidelines for sizing of vertical oil treaters. The procedures described in this blog entry do not give the overall dimensions of the treater, which may include inlet gas separation and free-water knockout sections, dependent on the upstream separation vessels. However, they do provide a method for specifying heat input required and a minimum size for the coalescing section (where the treating actually takes place), and provide the design engineer with tools to evaluate specific vendor proposals.Before going on to the sizing of the vertical treater let us understand the specific application of a vertical oil treater. The most common type of single-well onshore treater is the vertical treater, shown in the attached sketch. Vertical treaters are recommended where sand or other solid sediments are considered a potential problem.

Let us move on to the sizing equations for a vertical oil treater

Heat Input Requirements

Metric Units

q = 1100*Qo*ΔT*[0.5*(SG)o + (SG)w*Win /(100-Win)] ----------1(a)

USC Units

q = 15*Qo*ΔT*[0.5*(SG)o + (SG)w*Win /(100-Win)] -------1('b)

where:

q = Heat input, W (Btu/hr)

Qo = Oil flowrate, m3/hr (BOPD)

ΔT = Temperature increase, ⁰C(⁰F)

(SG)o = Oil specific gravity relative to water

(SG)w = Water specific gravity

Win = Inlet percent water cut, percent

Water Droplet Size

Metric Units

If µo< 7.0 x 10 –2 Pa s, then dm = 1361*Wc0.33*µo0.25 -----------2(a)

If µo≥ 7.0 x 10 –2 Pa s, then dm = 700*Wc0.33 ------------2('b)

USC Units

If µo< 70cP, then dm = 242*Wc0.33*µo0.25 -------------2('c)

If µo≥ 70cP, then dm = 700*Wc0.33 -------------------2(d)

µo = Oil viscosity, Pa s (cP)

dm = water droplet diameter, microns

Wc = Outlet Water Cut, percent

Vertical-Settling Time Equation

Metric Units

d = 806,000*(F*Qo*µo / (ΔSG*dm2))0.5 -------------------3(a)

USC Units

d = 81.8*(F*Qo*µo / (ΔSG*dm2))0.5 ---------------------3('b)

where:

d = vessel minimum diameter, mm (inch)

Qo = Oil flow rate, m3/h (BOPD)

µo = Oil viscosity, Pa s (cP)

ΔSG = Difference in specific gravity of oil & water

dm = water droplet diameter, microns

F = short-circuiting factor

=1, with very good flow distribution and smaller than 1220 mm (48 inch) diameter

or

= d/1220 (d/48) for treaters over 1220 mm (48 inch) diameter

Note:

First solve Eqn 3 using F=1. If the value of d is less than or equal to 1220 mm (48 inch), this is the final answer. If the value of d is greater than 1220 mm (48 inch), then substituting F = d/1220 (F = d/48) into above Eqn 3 gives the following modified equation:

Metric Units

d = 5.33*108*Qo*µo / (ΔSG*dm2) ----------------4(a)

USC Units

d = 139*Qo*µo / (ΔSG*dm2) --------------------4('b)

where:

d > 1220 mm (48 inch)

Note:

The height of the coalescing section for a vertical treater plays no part in the settling equation. The cross-sectional area of flow for upward velocity of the oil is a function of the diameter of the vessel alone.

Vertical-Retention Time Equation

The oil should be held at a temperature for a specific period of time to enable demulsifying the water-in-oil emulsion. This time can be best obtained by a laboratory bottle test. However, in absence of such data, 20-30 minutes is a good starting point.

Metric Units

d2*h = 2.12*107*F*(tr)o*Qo -----------------5(a)

USC Units

d2*h = 8.6*F*(tr)o*Qo ------------------------5('b)

where:

h = height of coalescing section, mm (inch)

(tr)o = Oil retention time, minutes (minutes)

Re-arranging Eqn 5 by substituting F, we get

Metric Units

If d ≤ 1220 mm (F = 1) then

h = 2.12*107*(tr)o*Qo / (d2) ---------------------6(a)

If d > 1220 mm (F = d/1220) then

h = 1.75*104*(tr)o*Qo / (d) ---------------------6('b)

USC Units

If d ≤ 48 inch (F = 1) then

h = 8.6*(tr)o*Qo / (d2) --------------------------6('c)

If d >48 inch (F = d/48) then

h = (tr)o*Qo / (5.58*d) -------------------------6(d)

Note:

Part of the overall vessel height is required to provide for water retention. The removal of oil from the water is not of primary concern.

Water-Retention Time Equation

Metric Units

hw = 2.12*107*(tr)w*Qw / (d2) ----------------7(a)

USC Units

hw = 8.6*(tr)w*Qw / (d2) -----------------------7('b)

where:

hw = height of water, mm (inch)

(tr)w = water retention time, minutes (minutes)

Qw = Water flow rate, m3/h (BOPD)

This concludes today's blog entry on sizing or adequacy check of vertical oil treaters, Readers are free to put up questions and I will try my best to answer them.

Regards,

Ankur

FB

FB