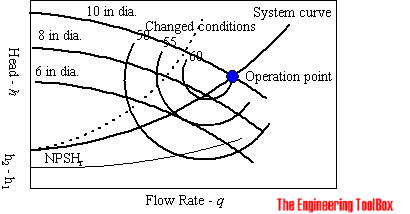

The Best Efficiency Point occurs when the pump system line and the pump operation line intersect

I just wanted to confirm my understanding that this is essentially saying that the BEP occurs when the NPSH required is equal to the desired discharged head, i.e. that there is no need for a pump since the required inlet pressure to the pump is equal to the desire outlet pressure?

If my first point is correct, then the pump will always operate on the system curve to the left of the BEP.

For any flow rate the

system curve indicates the system head, being the difference: discharge head -- suction head (head = pressure expressed as liquid height). It is not related to NPSHr, although the two curves happen to be beside each other on the specific diagram.

For any flow rate the

pump performance curve indicates the head (discharge head – suction head) delivered by the pump (for a given impeller and RPM).

The point where mentioned curves intersect is the operating point; pump will deliver this flow rate and head.

The operating point should not be far from best efficiency point of the pump, operating flow and head should not deviate more than 20% from flow and head indicated by the best efficiency point (according to a practice, of course the closer the better). Best efficiency point represents pump conditions of maximum efficiency, i.e. maximum of (mass flow * head)/absorbed power.

It is noted that frictional ΔP, static difference (H), operating pressure at end of discharge (Pd) & beginning of suction (Ps) line contribute to system head

It is also pointed out the operating pressure at pump suction would be Ps+Hs-ΔPs and at pump discharge Pd+Hd+ΔPd (s=suction, d=discharge, H=static difference relative to suction centerline), so pump differential pressure (Pd+Hd+ΔPd)-(Ps+Hs-ΔPs)=(Pd-Ps) + (Hd-Hs) + (ΔPd+ΔPs). The latter is often expressed in height of liquid being the pump head.

A worked out case would clarify the matter, if confusing, that is making the system curve by calculating several points of it. Examples can be found at E. Ludwig, Applied Process Design for Chemical and Petrochemical plants, Gulf 1977, Volume 1, Chapter 3, Pumping Systems and Performance.

Edited by kkala, 03 May 2010 - 11:51 PM.

FB

FB