Posted 28 June 2005 - 05:45 PM

D.R.Dave:

You are stating that industrial water-cooled oil coolers are expected to foul on the oil side as if it were a fact. It isn't. In truth, I have never applied a fouling factor to the oil side of my hydraulic oil coolers whether the oil were meant for lubrication of critical machinery or used as the hydraulic medium in presses or actuators. Let's get one thing straight: if your oil side is fouling while the oil is meant to lubricate critical machinery downstream, something is deadly wrong about your oil handling system. The oil should be 100% pure, filtered and clean. Now, the water side is another totally different issue. The fouling factor to be used on your water side is all in your hands. You are the only one controlling the quality of CWS (cooling water supply) and you should have the most accurate idea as to its condition.

If you are fouling in the oil side, you have dirty oil or are creating dirty oil within your system. You have a major problem that will result in gross maintenance problems in your machinery dependent for lubrication on this oil. I would find out how the oil is getting fouled and stop it immediately. Your oil system must be maintained 100% clean; if you can't maintain it this way, something is wrong and it should be corrected immediately.

There are no estimation methods for the oil's properties. One simply calls up or uses the plant's oil supplier or vendor for this information. The lube oil probably comes from a major refiner-producer (like Shell, Exxon, etc.) and they will gladly give you all this information in great detail.

As I stated, your oil system MUST BE MAINTAINED CLEAN. Since it is a clean system, there is no fouling and, therefore, no reason to open the oil side and to clean it. All oil coolers that I have employed have been totally sealed on the oil side. In fact, if you check major hydraulic or oil powered machinery, you will see that their oil coolers are sealed on the oil side and can't be opened by conventional means. This proves, or is in line with, my logic and assertions.

The baffle leakage on the shell side should be the same as is given to most all other applications and depends on the shop's quality of fabrication and the design employed. Unless you are designing the cooler - which I doubt - you have little concern with this clearance as long as the cooler's duty is warranted by the designer/fabricator that I assume you will purchase the unit from.

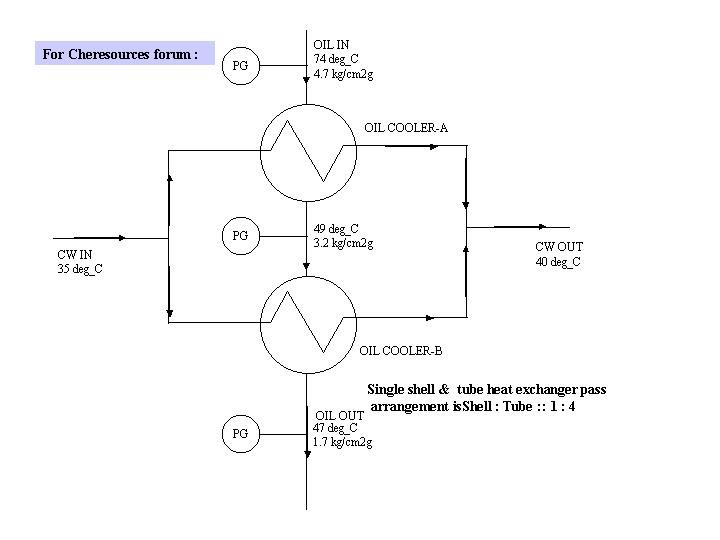

Whether you use one, two, or more coolers is all up to you. I would use one unit designed for the process temperatures specified. Normally, the outlet oil temperature will be in the order of 100 - 130 oF, depending on the gearbox specifications and the oil's viscosity required. So this is a moot issue that really isn't very important unless you want to spend more money using more coolers - which I don't think is the case here.

I don't understand your mention of an Aspen simulation. For what? I wouldn't simulate the performance of an oil cooler on Aspen; it isn't required for making the unit work correctly and I fail to see what results a simulator could reveal to me that I couldn't find out first-hand. Also, I've never heard of anyone using such an expensive simulator package to simulate the performance of a cooler. Either the design works according to the furnished specifications - or it doesn't. That's why an outside, expert, recognized designer and fabricator is selected for the oil cooler. If you do your job of selecting a competent designer/fabricator, you won't have any problems. That's the way that projects are put together all over the world.

One important note: you haven't even mentioned the quality of the CWS you are presently using and whether it is clean or fouling. I would certainly be more wary of the CWS before I suspected any contamination of the lubricating oil system. You also haven't said anything about the history of this fouling: is it recent or has it always behaved that way? Who specified it and who designed it? Was fouling of the oil anticipated? If it was, how then could they justify using it for lubricating a gear box and subjecting it to contamination and subsequent damage?

I'll await you reply to these concerns.

Art Montemayor

FB

FB