I would like to share my experience regarding Crude Distillation Unit Air-Cooled Overhead Condenser (later will be simply called as Condenser) in our Refinery. We have two CDUs and each of them is equipped with a number of banks of condenser. Each CDU (including the condensers) was designed by different vendor, so there is a difference in their manifold piping configuration.

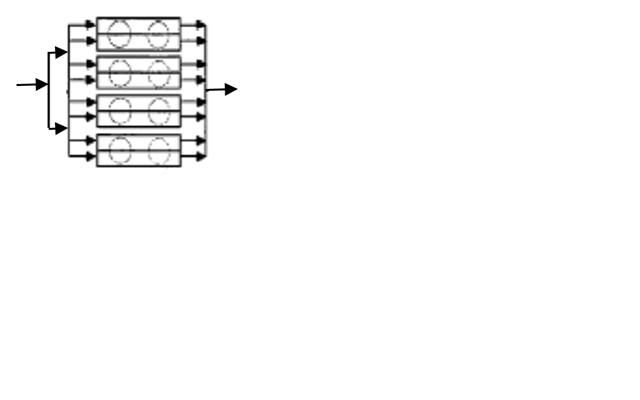

The first CDU has this kind of manifold arrangement:

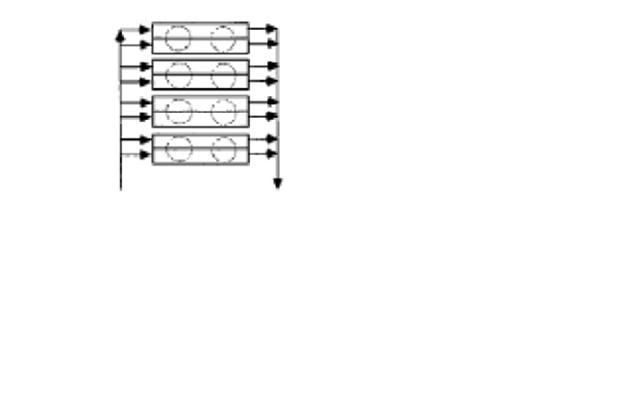

And the second CDU has this kind of manifold arrangement:

After years, we saw the significant difference between those two condensers in regards to their outlet temperature profile. For the first CDU condenser, we observe that there is a big variation in outlet temperature between each condenser bank. The coolest outlet temperature could be around 35 deg C while the hottest one could be more than 70 deg C (the inlet temperature is around 160 deg C). It means that the difference between the hottest and the coolest outlet temperature is about 40 deg C. Meanwhile, for the second CDU condenser the difference between the hottest and the coolest outlet temperature is only about 10 deg C. All fans work well and there is no significant difference in performance between fans in a same condenser.

Once I read a design practice from a process licensor mentioned that for one phase fluid (overhead of a column is considered as one phase fluid), the preferred/recommended manifold configuration is like the one we use in the second CDU.

My question is, does this manifold arrangement significantly affect the CDU condenser performance in providing proper flow distribution?

If somebody has any relevant idea, theory, or experience, please feel free to share.

Best regards and thanks in advance.

FB

FB