How about electric tracing?

Bobby

Bobby Strain

For me, it is good also to use electric tracing. Easy to control and installation not complicated as steam tracing (take from steam manifold, go back to condensate manifold, steam trap etc2). Just that they want to utilise the available steam at site plus there is nearby steam tracing manifold. I already communicate with THERMON representative in my country, they said, they is more to electrical tracing. However they can help on this matter for steam tracing.

Farid:

Breizh has given some good leads – especially the Thermon one. However, his lead doesn’t take you to the real source of all the Thermon design data and information. That URL is: http://www.thermon.c...eamtracing.aspx

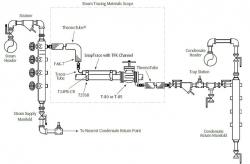

At this site you will find all the necessary and important information on designing and installing a successful steam tracing system. The basic secret of the Thermon design is the employment of their very successful thermal cement – which efficiently conducts the required heat transfer from the steam tubing to the target pipe wall.

I have used Thermon on many steam tracing applications and always had success. Note that they give you free design software that you can readily apply. I never “wrap” the steam tubing around the target pipe, but rather run a parallel tube (I favor 3/8”OD) on top or bottom of the pipe strapped and cemented. I attach a sample picture of a typical installation.

Thermon Steam Tracing Installation1.jpg

Thermon Steam Tracing Installation1.jpg

Art Montemayor

Thank you for the link. It really helps me in term of understanding the heat tracing philosophy. Already communicate with them. However, they are more to electrical tracing. I do prefer to use electrical tracing as it is easier to control and installation is less complex compared to steam. But I don’t really know in term of equipment cost, installation cost and operating cost which one is more economical. Based on client request, they preferred to use steam tracing as in plant practise mostly use steam. Actually, the need of the heat tracing is from piping icing problem. There is one piping suffer icing problem and caused the piping cant flow normally. Currently they just use steam from utility station to fix the problem.

breizh

thanks for the link. it really helpfull=)

FB

FB