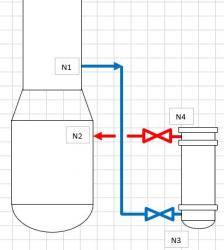

I'm currently looking at a once-through, vertical design (figure attached) for a project I'm working on.

I can provide numbers but I suppose a qualitative discussion should suffice for what I want to ask at this point.

Below is how I understand how the system works:

1. Liquid from column is taken at constant (L1).

2. Nozzle draw off in column (N1) location is higher than the reboiler outlet return nozzle in column (N2).

3. For the sake of discussion, we assume that reboiler outlet nozzle (N3) elevation is same with N2.

4. Flow goes across the reboiler from the bottom, going up.

5. If there's no heat input in the reboiler, the effective flow to the reboiler (L2) will be determined by the available static head (N1-N2) going against the total resistance of the circuit, which would be from the inlet and the outlet piping pressure drop, as well as the pressure drop inside the exchanger (with pure liquid flowing as heat input =0).

6. If L2 > L1, then you will draw more liquid than what's coming from the column, so it follows that the inlet piping to the reboiler will be partially filled with liquid. If L2 < L1, you will have back up of liquid in your column.

7. Exchanger elevation relative to column has little effect in L2.

If heat is applied to the reboiler:

8. You will have pressure drop increase in both reboiler outlet piping and inside the reboiler itself due to two phase flowing

9. However, the static head will change inside the reboiler due to presence of vapor.

10. In this case, point 7 no longer applies and change in exchanger elevation relative to column will have an effect in L2. I think this is the essence of doing the thermosyphon hydraulics, to establish the height required to make L2 = L1

Here are my questions:

1. My intuition tells me that if we follow the schematic above, you will always have driving force to establish flow and it is possible to have more driving force than required by the system to establish L1. If that's the case, shall I expect the reboiler inlet piping to be partially filled with liquid? Since the fluid is saturated, shall I expect flashing within this line?

2. We design the reboiler to provide enough surface area to allow a liquid with flow L1 to boil off to a target vapor fraction, for a given heat duty (and steam flow, by extension). In reality, if the flow to the reboiler is different from design (say L2 > L1), you will produce a different vapor fraction at your reboiler process outlet, and the heat duty may be different from design since your heat transfer coefficient might change due to differences in boiling regime. How do we ensure that we are designing the thermosyphon circuit will actually work as intended?

FB

FB